Machines

Metal Tinplate Sheet Four Color Printing Machine

产品编号:

1051327726272471040

Model:

YTJS-4

Operation:

Automatic

Application:

Metal Sheet Color Decorated Printing

Can size:

Various

Speed:

up to 6,000 sheets/Hour

Classification:

keyword:

METAL SHEET FOUR COLOR PRINTER

METAL SHEET FOUR COLOR PRINTING MACHINE

Product Overview

Metal Tinplate Sheet Four Color Printing Machine

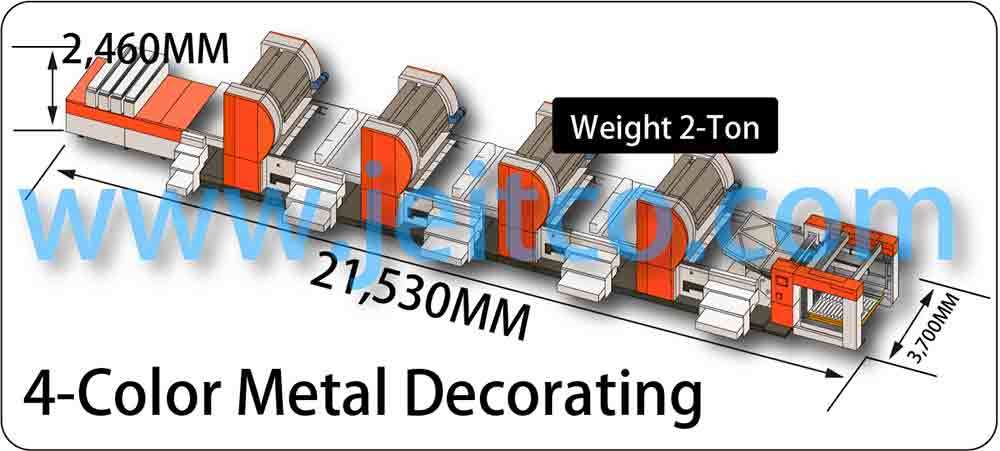

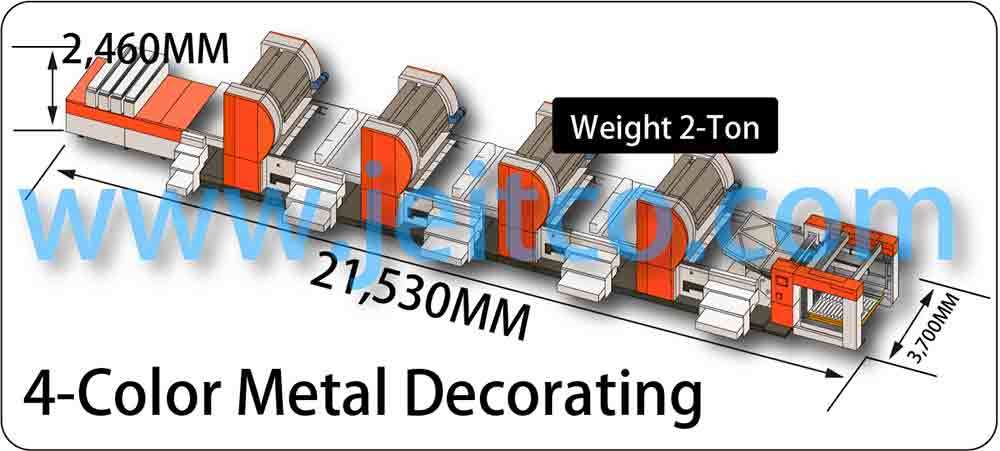

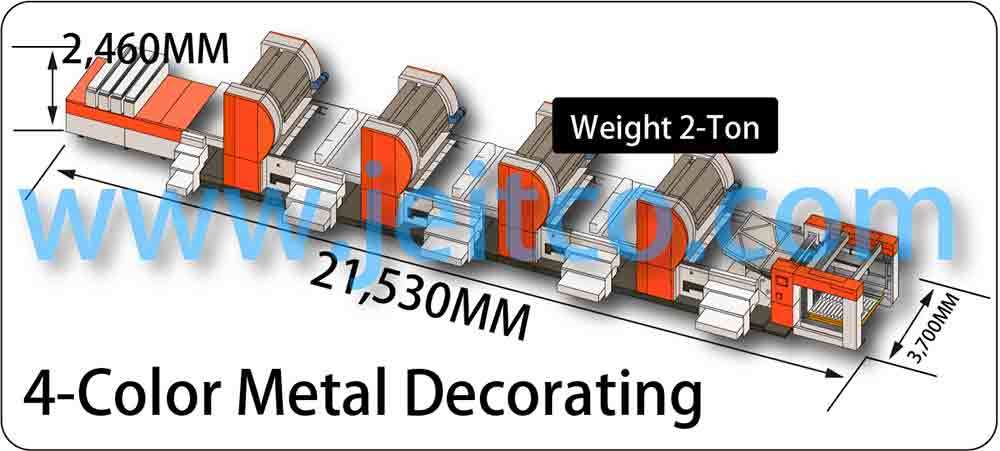

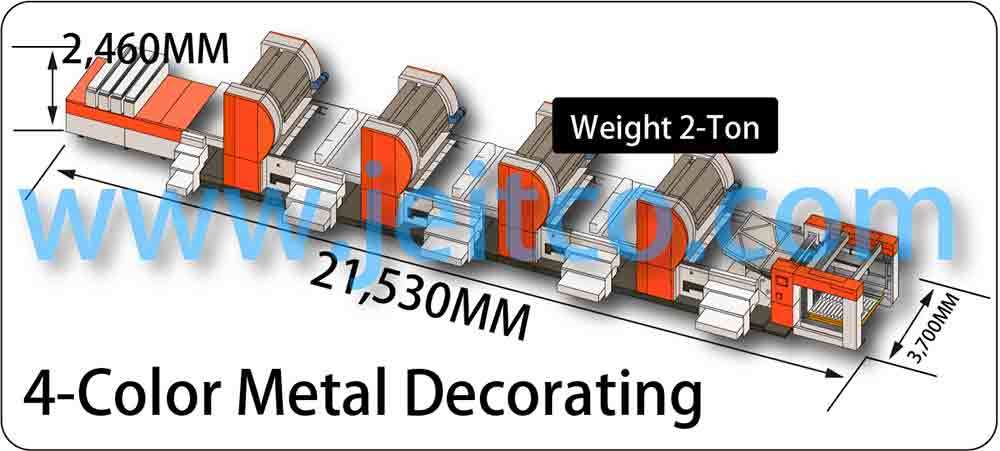

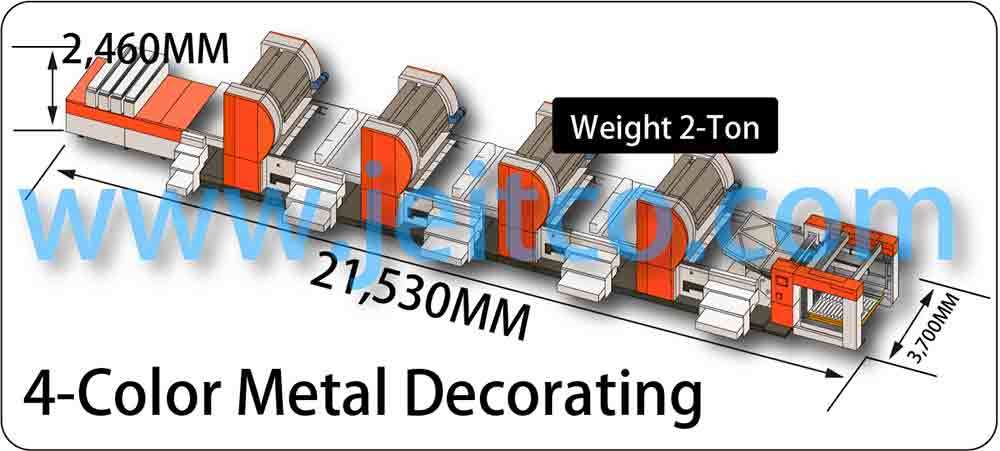

4-Color Metal Sheet Printer + LED UV Curing Sys. + 3-stacking device:

- Model: RYYT4453W;

- Max. Sheet Size: 1,145 x 960 (mm);

- Min. Sheet Size: 712 X 510 (mm);

- Metal Thickness: 0.15-0.40(mm);

- Max Printing Area: 1,135 x 945 (mm);

- Printing Board Size: 1,160 x 1,040 x 0.3(mm);

- Rubber Size: 1,175 x 1,120 x 1.9(mm);

- Blank Edge: 3-5(mm);

- Conveyor Height: 916mm;

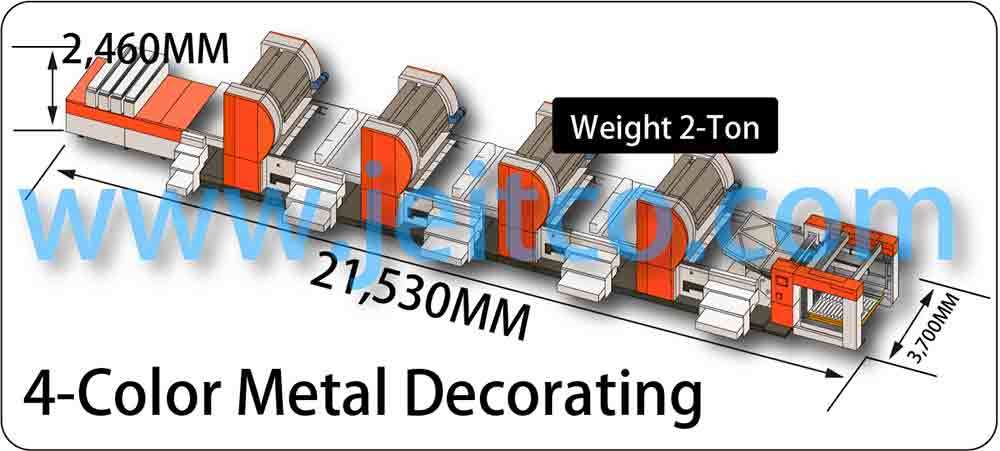

- Max. Weight of Loading Stacking Device: 2-Ton approx.;

- Main Power: 17kw X 4sets;

- Printer Dimenions: L22,300 x W3,700 x H2,460(mm);

- Built-in LED UV Curing Sys. for 4-color metal printer;

- Built-in 3sets of Metal Sheet Stacking Devices;

- Servo Control Sys.: SIEMENS;

- Servo Motor: SIEMENS;

- Main Program Control Sys.: SIEMENS;

- Extension Unit: SIEMENS;

- Extension Module: SIEMENS;

- Built-in Sheet Feeder;

- Built-in 4-group Conveyor Table;

- Built-in Main 4-group Printer;

- Built-in 4-group Out-feeder;

- Built-in 4-group Main Control Cabinet;

- Built-in 4-group Automatic Ink-clean Device;

- Built-in Automatic Ink-adjust Device (36-Ink Area);

- Built-in 4-group Metal Sheet Push-feed Adjusting Device;

- Built-in 4-group Anti-Ghost Device;

- Built-in Central Remote Control System;

Technical performance:

☑️The main transmission gear is located in the machine's shield, full lubrication and long life;

☑️Three printing rollers with vertical arrangement, easy to operate:

☑️Print roller bearings are imported precision bearings to ensure that the rotation accuracy:

☑️ by the roller pressure adjustment structure advanced, easy to operate;

☑️Adopting shaftless transmission technology, each color group is independent of each other and can be installed and wiped drum at the same time;

☑️The use of synchronous transmission between color groups, through the virtual spindle as a reference, to achieve high-precision synchronization

☑️Roller with hard lining, printing dot strong, clear;

☑️adopt the cam high point closed teeth, reliable positioning, overprint accurate;

☑️Plate cylinder alcohol dampening, bright ink printed goods;

☑️by version of the roller cylinder clutch cylinder driven, simple structure, reliable work;

☑️Water roller, ink roller by a separate inverter motor drive, stepless speed regulation, synchronization with the host to achieve speed tracking;

☑️scientific and reasonable roller arrangement to ensure that the system for ink quality:

☑️The ink system and dampening system can be driven and disengaged with the host machine according to the need to avoid the dry wear of the rubber roller:

☑️man-machine interface, intuitive screen, easy to grasp, easy to operate:

☑️Feeding machine and the host synchronization can not stop machine electric regulation, effectively shorten the auxiliary time;

☑️using fixed-point, quantitative, time lubrication system, full lubrication without oil leakage.

Technical Parameters:

|

Max.Sheet Size

|

1,145 X 965mm

|

|

Min. Sheet Size

|

712 X 508mm

|

|

Thickness of sheet metal

|

0.16-0.50mm

|

|

The largest printing area

|

1,135 X 945mm

|

|

Plate Size

|

1,160 X 10,40 X 0.3mm

|

|

Blanket Size

|

1,175 X 1,135 X 1.9mm |

|

Diao mouth white edge size

|

5mm

|

|

The maximum speed of the machine

|

6,000 sheets / hour

|

|

Printing Speed

|

According to the printing parameters to determine

|

|

Maximum Stacking Weight

|

2 Tons

|

|

Machine size

(length X width X height)

|

L21,530 X W3,700 X H2,460mm

(with inspection table) L18,580 X W3,700 X H2,460mm (without inspection table) |

4-Color Metal Sheet Printer + LED UV Curing Sys. + 3-stacking device:

- Model: RYYT4453W;

- Max. Sheet Size: 1,145 x 960 (mm);

- Min. Sheet Size: 712 X 510 (mm);

- Metal Thickness: 0.15-0.40(mm);

- Max Printing Area: 1,135 x 945 (mm);

- Printing Board Size: 1,160 x 1,040 x 0.3(mm);

- Rubber Size: 1,175 x 1,120 x 1.9(mm);

- Blank Edge: 3-5(mm);

- Conveyor Height: 916mm;

- Max. Weight of Loading Stacking Device: 2-Ton approx.;

- Main Power: 17kw X 4sets;

- Printer Dimenions: L22,300 x W3,700 x H2,460(mm);

- Built-in LED UV Curing Sys. for 4-color metal printer;

- Built-in 3sets of Metal Sheet Stacking Devices;

- Servo Control Sys.: SIEMENS;

- Servo Motor: SIEMENS;

- Main Program Control Sys.: SIEMENS;

- Extension Unit: SIEMENS;

- Extension Module: SIEMENS;

- Built-in Sheet Feeder;

- Built-in 4-group Conveyor Table;

- Built-in Main 4-group Printer;

- Built-in 4-group Out-feeder;

- Built-in 4-group Main Control Cabinet;

- Built-in 4-group Automatic Ink-clean Device;

- Built-in Automatic Ink-adjust Device (36-Ink Area);

- Built-in 4-group Metal Sheet Push-feed Adjusting Device;

- Built-in 4-group Anti-Ghost Device;

- Built-in Central Remote Control System;

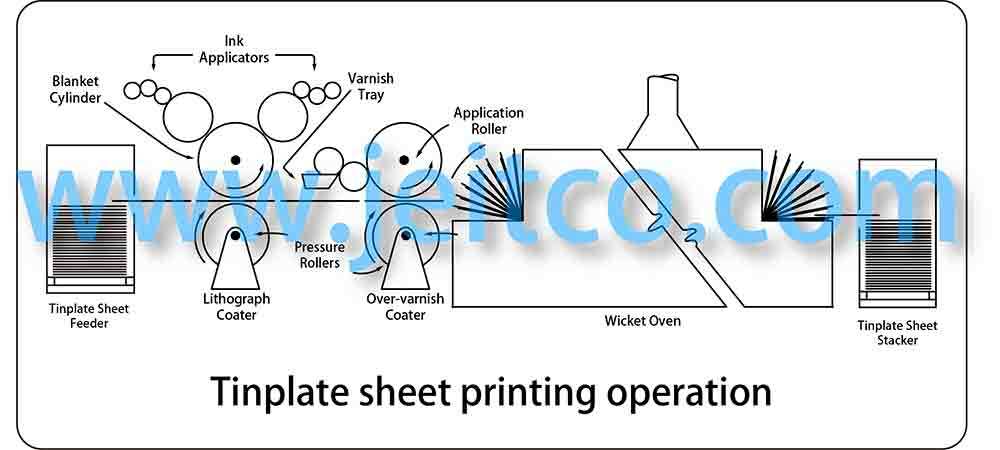

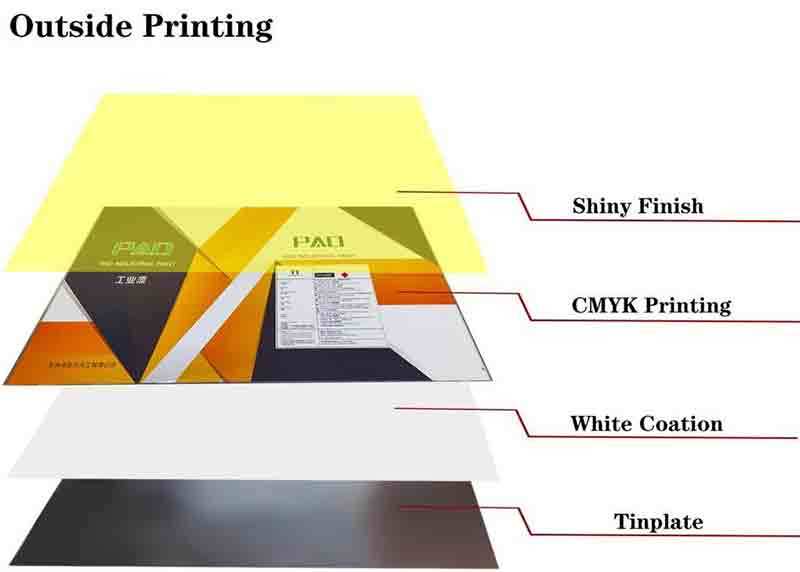

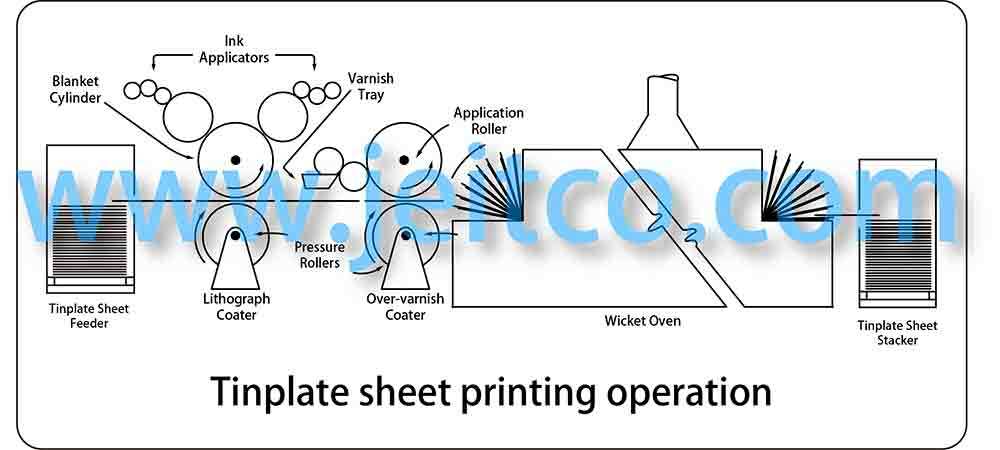

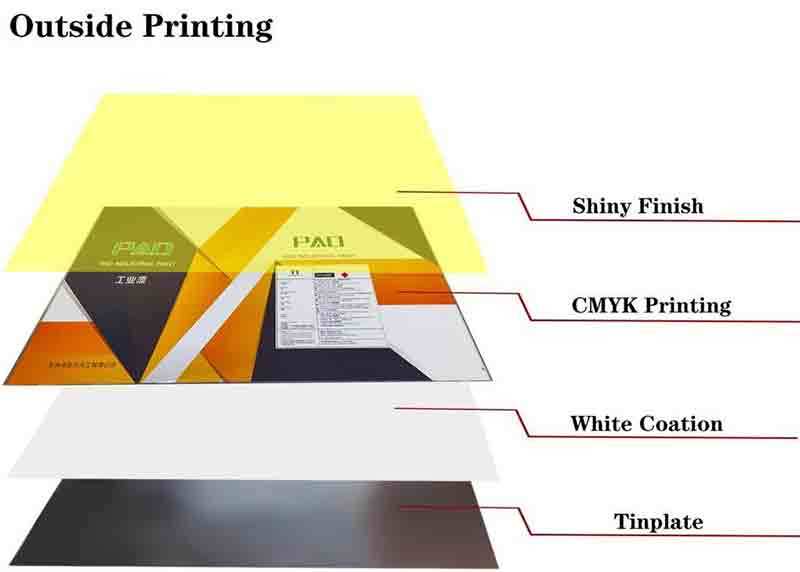

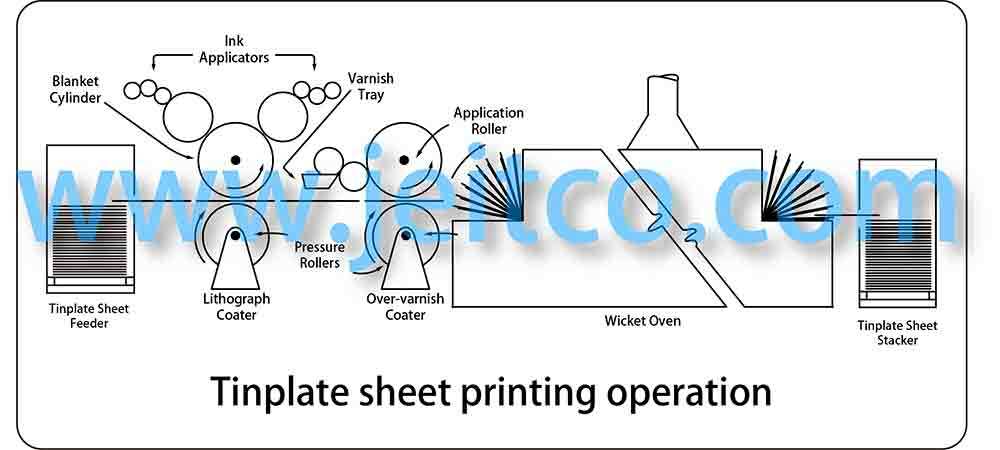

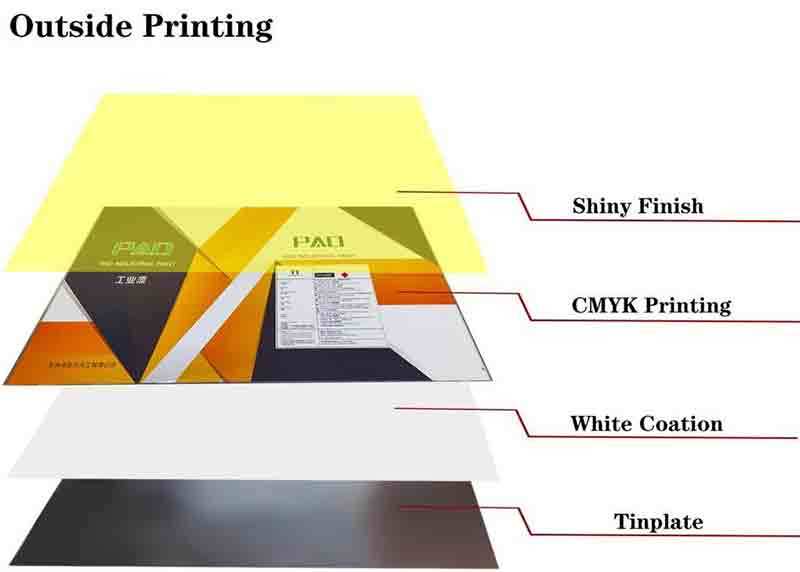

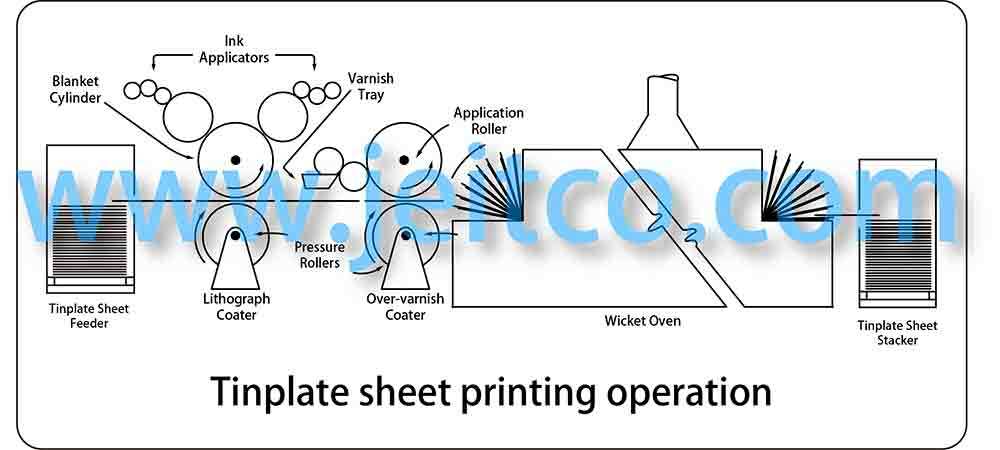

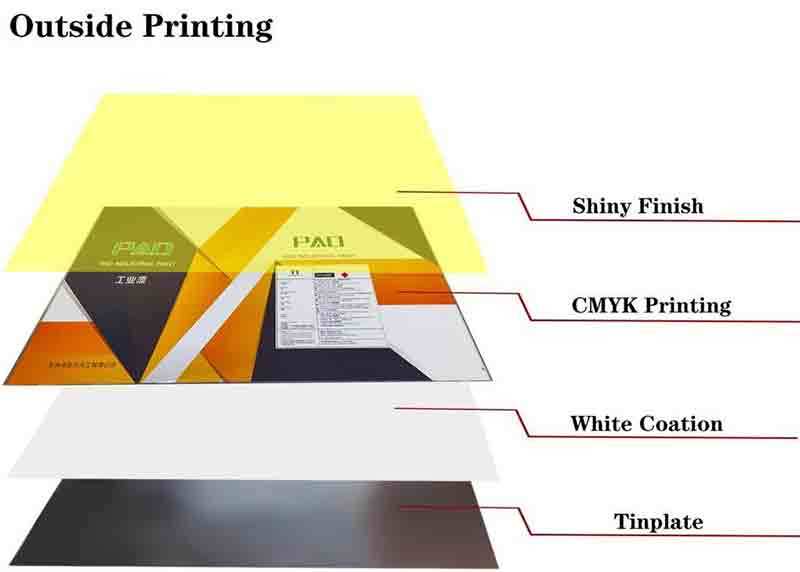

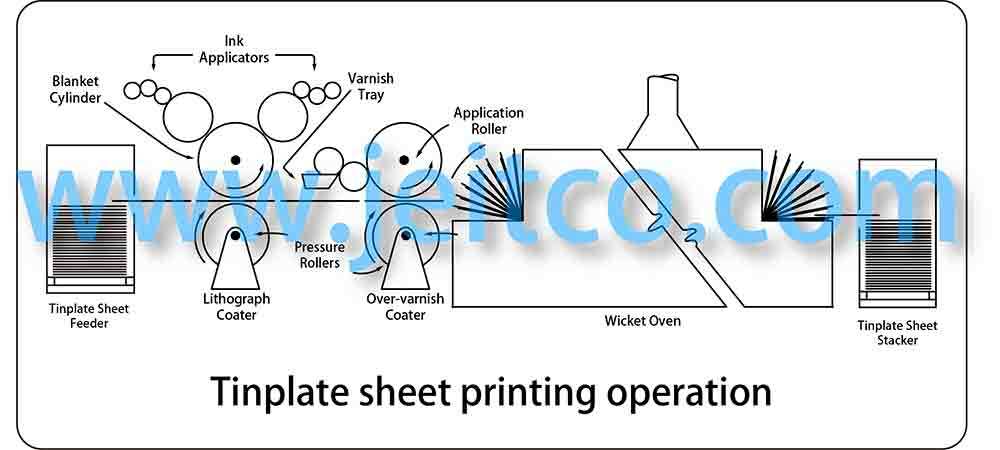

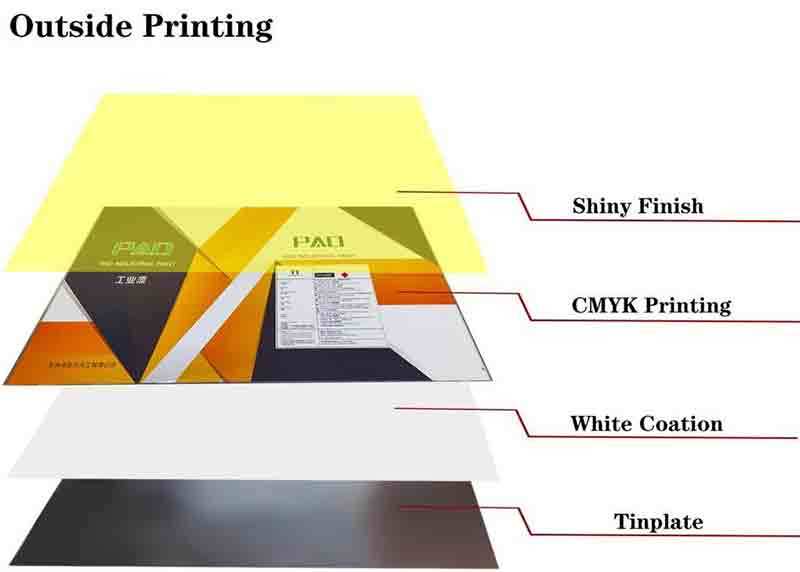

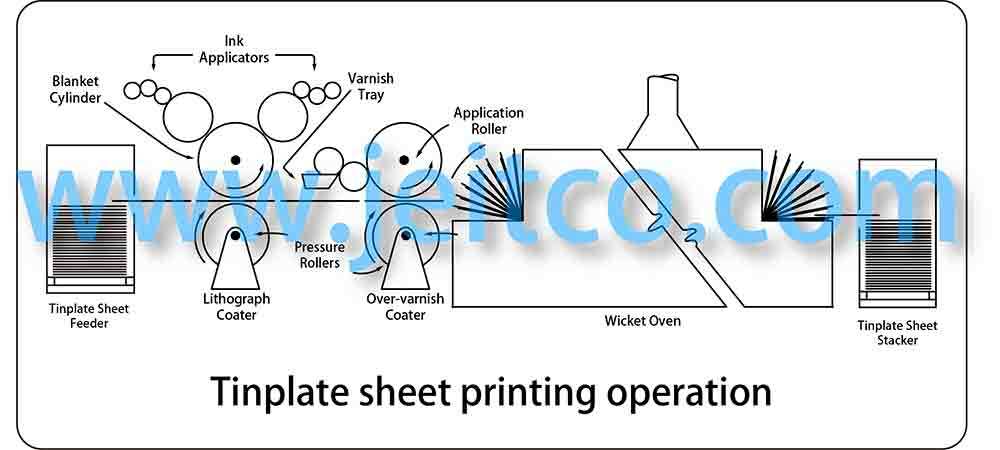

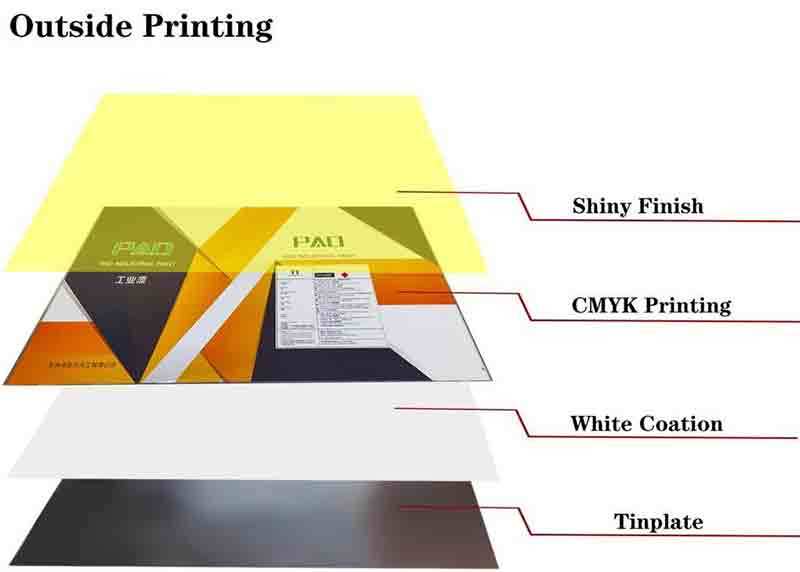

Color-printed metal, which is bright-colored, shiny and rust-resistance, can be used in replacement of paper labels to make metal tin cans look more beautiful and attractive to consumers, prevent fakery and indicate product instructions. With the use of large quantities of LTS and TFS plates, color-printed metal has become an important choice for consuming such plates, and there has been a rapid increase in application of label printing to can bodies and can covers.

Coatings used for color printing including primers such as alkyd, acrylic, epoxy amino, epoxy ester, polyester, and vinyl as well as white coatings and polishing vanishes. Besides, there are also printing inks of various colors.

4-Color Metal Sheet Printer + LED UV Curing Sys. + 3-stacking device:

- Model: RYYT4453W;

- Max. Sheet Size: 1,145 x 960 (mm);

- Min. Sheet Size: 712 X 510 (mm);

- Metal Thickness: 0.15-0.40(mm);

- Max Printing Area: 1,135 x 945 (mm);

- Printing Board Size: 1,160 x 1,040 x 0.3(mm);

- Rubber Size: 1,175 x 1,120 x 1.9(mm);

- Blank Edge: 3-5(mm);

- Conveyor Height: 916mm;

- Max. Weight of Loading Stacking Device: 2-Ton approx.;

- Main Power: 17kw X 4sets;

- Printer Dimenions: L22,300 x W3,700 x H2,460(mm);

- Built-in LED UV Curing Sys. for 4-color metal printer;

- Built-in 3sets of Metal Sheet Stacking Devices;

- Servo Control Sys.: SIEMENS;

- Servo Motor: SIEMENS;

- Main Program Control Sys.: SIEMENS;

- Extension Unit: SIEMENS;

- Extension Module: SIEMENS;

- Built-in Sheet Feeder;

- Built-in 4-group Conveyor Table;

- Built-in Main 4-group Printer;

- Built-in 4-group Out-feeder;

- Built-in 4-group Main Control Cabinet;

- Built-in 4-group Automatic Ink-clean Device;

- Built-in Automatic Ink-adjust Device (36-Ink Area);

- Built-in 4-group Metal Sheet Push-feed Adjusting Device;

- Built-in 4-group Anti-Ghost Device;

- Built-in Central Remote Control System;

Color-printed metal, which is bright-colored, shiny and rust-resistance, can be used in replacement of paper labels to make metal tin cans look more beautiful and attractive to consumers, prevent fakery and indicate product instructions. With the use of large quantities of LTS and TFS plates, color-printed metal has become an important choice for consuming such plates, and there has been a rapid increase in application of label printing to can bodies and can covers.

Coatings used for color printing including primers such as alkyd, acrylic, epoxy amino, epoxy ester, polyester, and vinyl as well as white coatings and polishing vanishes. Besides, there are also printing inks of various colors.

4-Color Metal Sheet Printer + LED UV Curing Sys. + 3-stacking device:

- Model: RYYT4453W;

- Max. Sheet Size: 1,145 x 960 (mm);

- Min. Sheet Size: 712 X 510 (mm);

- Metal Thickness: 0.15-0.40(mm);

- Max Printing Area: 1,135 x 945 (mm);

- Printing Board Size: 1,160 x 1,040 x 0.3(mm);

- Rubber Size: 1,175 x 1,120 x 1.9(mm);

- Blank Edge: 3-5(mm);

- Conveyor Height: 916mm;

- Max. Weight of Loading Stacking Device: 2-Ton approx.;

- Main Power: 17kw X 4sets;

- Printer Dimenions: L22,300 x W3,700 x H2,460(mm);

- Built-in LED UV Curing Sys. for 4-color metal printer;

- Built-in 3sets of Metal Sheet Stacking Devices;

- Servo Control Sys.: SIEMENS;

- Servo Motor: SIEMENS;

- Main Program Control Sys.: SIEMENS;

- Extension Unit: SIEMENS;

- Extension Module: SIEMENS;

- Built-in Sheet Feeder;

- Built-in 4-group Conveyor Table;

- Built-in Main 4-group Printer;

- Built-in 4-group Out-feeder;

- Built-in 4-group Main Control Cabinet;

- Built-in 4-group Automatic Ink-clean Device;

- Built-in Automatic Ink-adjust Device (36-Ink Area);

- Built-in 4-group Metal Sheet Push-feed Adjusting Device;

- Built-in 4-group Anti-Ghost Device;

- Built-in Central Remote Control System;

Color-printed metal, which is bright-colored, shiny and rust-resistance, can be used in replacement of paper labels to make metal tin cans look more beautiful and attractive to consumers, prevent fakery and indicate product instructions. With the use of large quantities of LTS and TFS plates, color-printed metal has become an important choice for consuming such plates, and there has been a rapid increase in application of label printing to can bodies and can covers.

Coatings used for color printing including primers such as alkyd, acrylic, epoxy amino, epoxy ester, polyester, and vinyl as well as white coatings and polishing vanishes. Besides, there are also printing inks of various colors.

4-Color Metal Sheet Printer + LED UV Curing Sys. + 3-stacking device:

- Model: RYYT4453W;

- Max. Sheet Size: 1,145 x 960 (mm);

- Min. Sheet Size: 712 X 510 (mm);

- Metal Thickness: 0.15-0.40(mm);

- Max Printing Area: 1,135 x 945 (mm);

- Printing Board Size: 1,160 x 1,040 x 0.3(mm);

- Rubber Size: 1,175 x 1,120 x 1.9(mm);

- Blank Edge: 3-5(mm);

- Conveyor Height: 916mm;

- Max. Weight of Loading Stacking Device: 2-Ton approx.;

- Main Power: 17kw X 4sets;

- Printer Dimenions: L22,300 x W3,700 x H2,460(mm);

- Built-in LED UV Curing Sys. for 4-color metal printer;

- Built-in 3sets of Metal Sheet Stacking Devices;

- Servo Control Sys.: SIEMENS;

- Servo Motor: SIEMENS;

- Main Program Control Sys.: SIEMENS;

- Extension Unit: SIEMENS;

- Extension Module: SIEMENS;

- Built-in Sheet Feeder;

- Built-in 4-group Conveyor Table;

- Built-in Main 4-group Printer;

- Built-in 4-group Out-feeder;

- Built-in 4-group Main Control Cabinet;

- Built-in 4-group Automatic Ink-clean Device;

- Built-in Automatic Ink-adjust Device (36-Ink Area);

- Built-in 4-group Metal Sheet Push-feed Adjusting Device;

- Built-in 4-group Anti-Ghost Device;

- Built-in Central Remote Control System;

Color-printed metal, which is bright-colored, shiny and rust-resistance, can be used in replacement of paper labels to make metal tin cans look more beautiful and attractive to consumers, prevent fakery and indicate product instructions. With the use of large quantities of LTS and TFS plates, color-printed metal has become an important choice for consuming such plates, and there has been a rapid increase in application of label printing to can bodies and can covers.

Coatings used for color printing including primers such as alkyd, acrylic, epoxy amino, epoxy ester, polyester, and vinyl as well as white coatings and polishing vanishes. Besides, there are also printing inks of various colors.

4-Color Metal Sheet Printer + LED UV Curing Sys. + 3-stacking device:

- Model: RYYT4453W;

- Max. Sheet Size: 1,145 x 960 (mm);

- Min. Sheet Size: 712 X 510 (mm);

- Metal Thickness: 0.15-0.40(mm);

- Max Printing Area: 1,135 x 945 (mm);

- Printing Board Size: 1,160 x 1,040 x 0.3(mm);

- Rubber Size: 1,175 x 1,120 x 1.9(mm);

- Blank Edge: 3-5(mm);

- Conveyor Height: 916mm;

- Max. Weight of Loading Stacking Device: 2-Ton approx.;

- Main Power: 17kw X 4sets;

- Printer Dimenions: L22,300 x W3,700 x H2,460(mm);

- Built-in LED UV Curing Sys. for 4-color metal printer;

- Built-in 3sets of Metal Sheet Stacking Devices;

- Servo Control Sys.: SIEMENS;

- Servo Motor: SIEMENS;

- Main Program Control Sys.: SIEMENS;

- Extension Unit: SIEMENS;

- Extension Module: SIEMENS;

- Built-in Sheet Feeder;

- Built-in 4-group Conveyor Table;

- Built-in Main 4-group Printer;

- Built-in 4-group Out-feeder;

- Built-in 4-group Main Control Cabinet;

- Built-in 4-group Automatic Ink-clean Device;

- Built-in Automatic Ink-adjust Device (36-Ink Area);

- Built-in 4-group Metal Sheet Push-feed Adjusting Device;

- Built-in 4-group Anti-Ghost Device;

- Built-in Central Remote Control System;

Color-printed metal, which is bright-colored, shiny and rust-resistance, can be used in replacement of paper labels to make metal tin cans look more beautiful and attractive to consumers, prevent fakery and indicate product instructions. With the use of large quantities of LTS and TFS plates, color-printed metal has become an important choice for consuming such plates, and there has been a rapid increase in application of label printing to can bodies and can covers.

Coatings used for color printing including primers such as alkyd, acrylic, epoxy amino, epoxy ester, polyester, and vinyl as well as white coatings and polishing vanishes. Besides, there are also printing inks of various colors.

Related Products