Machines

CTP for Metal Sheet Offset Printer

| Item | Specifications |

| Structure | External Drum Type |

| Light | 830nm Laser Diode |

| Precision | 2,400dpi |

| Speed | Min. 12sheets/hr |

| Plate Size (H*W) | Max.1,230*1,130mm, Min. 450*320mm ( can work with KBA Metal Star Series Max. Tinplate Format 1,220 x 1,095 x 0.40mm) |

| Plate Thickness | 0.15-0.40mm |

| Repeat Precision | +/-5 um |

| Mesh Re-Indication (Dot Percentage Area) |

1%~99% |

| Registration Precision | <0.01mm Margin-auto-laser-inspection & auto registration |

| Positioning Precision | 0.2mm |

| Laser Service Life | Min. 10,000 hrs |

| Blowing Chiller | Built-in |

| Remote Diagnosis | Available . |

| Dusting System | Built-in |

| Plates Available | Thermo CTP Plate |

| Diode Laser Feature | Intelligent, Auto-screening, Extended Service Life |

| Plate Load & Unload | Auto Loading, Auto Unloading; Vacuum Sucking |

| Plate Balancing | Auto balancing |

| Data Interface | USB,1,000Mbit/s |

| Constant Temperature. Control | Auto Temperature Equilibrator |

| Working Condition | 25℃+3℃ operation temp. 20~80%relative humidity |

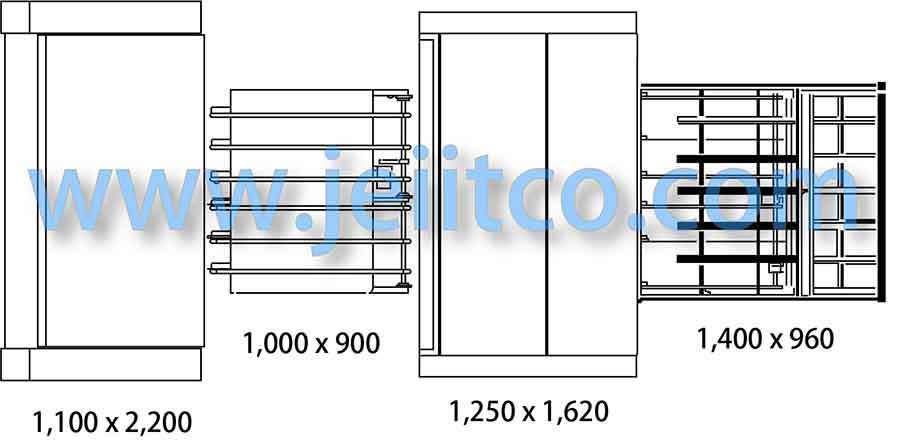

| Machine Dimension | 2,200mm*1,100mm*1,050mm |

| N.W. | 1,500Kg |

| Electricity | 4.2KW/220V+5%,50/60Hz |

| Port | CIP3/CIP4 |

| Light Roller Rotate Speed | 800rpm-900rpm Industry AVG. 600rpm; 50% higher Stability than usual with smaller size drum |

| Plate-in Method | High Pressure Air, Touch-free Plate-in |

| Plate Absorb Method | 3 Chamber Sucking, Auto Sucking Area Adjustable subject to Plate Size, Free of Waving & Floating |

| Optic Lens Running Method | maglev |

| Line-adding Method | Frequency-adjustable, Format-adjustable, Mix-adding methods. Bi-digital halftone processing specially for metal printing. Dot output ratio control for color deviation. |

| Color Management | In-line with types of presses, Output preset data for printing |

| Processor Data. | 1. Connection method: straight ; 2. PLC touch screen panel, problem auto indication ; 3. Precisely control 0.1℃ ; 4. Auto dynamic/static rehydration system ; 5. Auto glue-cleaning, and glue recycling, auto-lubrication; 6. Max processing size 1250mm ; 7. Plate thickness:0.15mm~0.40mm ; |

| Stacker (1 SET) | 1. Auto-stacking ; 2. Suit to CTP system request ; |

| Conveyor (1SET) | 1. Straight conveyor; 2. Suit to CTP system request ; |

| CTP server (1SET) | fits CTP system request, operation system pre-installed. |

| UPS | UPS 10KW Built-in Battery, In-line |

| CTP Control Computer | CPU:Dual-core,Memory:4G,Storage:500G |

STP-S THERMAL CTP PLATE

ALLSTP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

Description:

STP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

SPECIFICATION

Type: Positive Thermal CTP plate;

Spectral Sensitivity: 830nm;

Exposure Energy: 110~130mj/cm²;

Resolution: 200 lpi( 1~99% );

Run-length: 100,000~200,000 ( UV-INK );

200,000~400,000 ( Ordinary ink );

*Run-Length varies with its printing conditions and imaging content

ADVANTAGES

(1) UV-ink resistance;

(2)Low energy required;

(4)Compatible with all standard CTP setters;

| Item | Specifications |

| Structure | External Drum Type |

| Light | 830nm Laser Diode |

| Precision | 2,400dpi |

| Speed | Min. 12sheets/hr |

| Plate Size (H*W) | Max.1,230*1,130mm, Min. 450*320mm ( can work with KBA Metal Star Series Max. Tinplate Format 1,220 x 1,095 x 0.40mm) |

| Plate Thickness | 0.15-0.40mm |

| Repeat Precision | +/-5 um |

| Mesh Re-Indication (Dot Percentage Area) |

1%~99% |

| Registration Precision | <0.01mm Margin-auto-laser-inspection & auto registration |

| Positioning Precision | 0.2mm |

| Laser Service Life | Min. 10,000 hrs |

| Blowing Chiller | Built-in |

| Remote Diagnosis | Available . |

| Dusting System | Built-in |

| Plates Available | Thermo CTP Plate |

| Diode Laser Feature | Intelligent, Auto-screening, Extended Service Life |

| Plate Load & Unload | Auto Loading, Auto Unloading; Vacuum Sucking |

| Plate Balancing | Auto balancing |

| Data Interface | USB,1,000Mbit/s |

| Constant Temperature. Control | Auto Temperature Equilibrator |

| Working Condition | 25℃+3℃ operation temp. 20~80%relative humidity |

| Machine Dimension | 2,200mm*1,100mm*1,050mm |

| N.W. | 1,500Kg |

| Electricity | 4.2KW/220V+5%,50/60Hz |

| Port | CIP3/CIP4 |

| Light Roller Rotate Speed | 800rpm-900rpm Industry AVG. 600rpm; 50% higher Stability than usual with smaller size drum |

| Plate-in Method | High Pressure Air, Touch-free Plate-in |

| Plate Absorb Method | 3 Chamber Sucking, Auto Sucking Area Adjustable subject to Plate Size, Free of Waving & Floating |

| Optic Lens Running Method | maglev |

| Line-adding Method | Frequency-adjustable, Format-adjustable, Mix-adding methods. Bi-digital halftone processing specially for metal printing. Dot output ratio control for color deviation. |

| Color Management | In-line with types of presses, Output preset data for printing |

| Processor Data. | 1. Connection method: straight ; 2. PLC touch screen panel, problem auto indication ; 3. Precisely control 0.1℃ ; 4. Auto dynamic/static rehydration system ; 5. Auto glue-cleaning, and glue recycling, auto-lubrication; 6. Max processing size 1250mm ; 7. Plate thickness:0.15mm~0.40mm ; |

| Stacker (1 SET) | 1. Auto-stacking ; 2. Suit to CTP system request ; |

| Conveyor (1SET) | 1. Straight conveyor; 2. Suit to CTP system request ; |

| CTP server (1SET) | fits CTP system request, operation system pre-installed. |

| UPS | UPS 10KW Built-in Battery, In-line |

| CTP Control Computer | CPU:Dual-core,Memory:4G,Storage:500G |

STP-S THERMAL CTP PLATE

ALLSTP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

Description:

STP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

SPECIFICATION

Type: Positive Thermal CTP plate;

Spectral Sensitivity: 830nm;

Exposure Energy: 110~130mj/cm²;

Resolution: 200 lpi( 1~99% );

Run-length: 100,000~200,000 ( UV-INK );

200,000~400,000 ( Ordinary ink );

*Run-Length varies with its printing conditions and imaging content

ADVANTAGES

(1) UV-ink resistance;

(2)Low energy required;

(4)Compatible with all standard CTP setters;

| Item | Specifications |

| Structure | External Drum Type |

| Light | 830nm Laser Diode |

| Precision | 2,400dpi |

| Speed | Min. 12sheets/hr |

| Plate Size (H*W) | Max.1,230*1,130mm, Min. 450*320mm ( can work with KBA Metal Star Series Max. Tinplate Format 1,220 x 1,095 x 0.40mm) |

| Plate Thickness | 0.15-0.40mm |

| Repeat Precision | +/-5 um |

| Mesh Re-Indication (Dot Percentage Area) |

1%~99% |

| Registration Precision | <0.01mm Margin-auto-laser-inspection & auto registration |

| Positioning Precision | 0.2mm |

| Laser Service Life | Min. 10,000 hrs |

| Blowing Chiller | Built-in |

| Remote Diagnosis | Available . |

| Dusting System | Built-in |

| Plates Available | Thermo CTP Plate |

| Diode Laser Feature | Intelligent, Auto-screening, Extended Service Life |

| Plate Load & Unload | Auto Loading, Auto Unloading; Vacuum Sucking |

| Plate Balancing | Auto balancing |

| Data Interface | USB,1,000Mbit/s |

| Constant Temperature. Control | Auto Temperature Equilibrator |

| Working Condition | 25℃+3℃ operation temp. 20~80%relative humidity |

| Machine Dimension | 2,200mm*1,100mm*1,050mm |

| N.W. | 1,500Kg |

| Electricity | 4.2KW/220V+5%,50/60Hz |

| Port | CIP3/CIP4 |

| Light Roller Rotate Speed | 800rpm-900rpm Industry AVG. 600rpm; 50% higher Stability than usual with smaller size drum |

| Plate-in Method | High Pressure Air, Touch-free Plate-in |

| Plate Absorb Method | 3 Chamber Sucking, Auto Sucking Area Adjustable subject to Plate Size, Free of Waving & Floating |

| Optic Lens Running Method | maglev |

| Line-adding Method | Frequency-adjustable, Format-adjustable, Mix-adding methods. Bi-digital halftone processing specially for metal printing. Dot output ratio control for color deviation. |

| Color Management | In-line with types of presses, Output preset data for printing |

| Processor Data. | 1. Connection method: straight ; 2. PLC touch screen panel, problem auto indication ; 3. Precisely control 0.1℃ ; 4. Auto dynamic/static rehydration system ; 5. Auto glue-cleaning, and glue recycling, auto-lubrication; 6. Max processing size 1250mm ; 7. Plate thickness:0.15mm~0.40mm ; |

| Stacker (1 SET) | 1. Auto-stacking ; 2. Suit to CTP system request ; |

| Conveyor (1SET) | 1. Straight conveyor; 2. Suit to CTP system request ; |

| CTP server (1SET) | fits CTP system request, operation system pre-installed. |

| UPS | UPS 10KW Built-in Battery, In-line |

| CTP Control Computer | CPU:Dual-core,Memory:4G,Storage:500G |

STP-S THERMAL CTP PLATE

ALLSTP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

Description:

STP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

SPECIFICATION

Type: Positive Thermal CTP plate;

Spectral Sensitivity: 830nm;

Exposure Energy: 110~130mj/cm²;

Resolution: 200 lpi( 1~99% );

Run-length: 100,000~200,000 ( UV-INK );

200,000~400,000 ( Ordinary ink );

*Run-Length varies with its printing conditions and imaging content

ADVANTAGES

(1) UV-ink resistance;

(2)Low energy required;

(4)Compatible with all standard CTP setters;

| Item | Specifications |

| Structure | External Drum Type |

| Light | 830nm Laser Diode |

| Precision | 2,400dpi |

| Speed | Min. 12sheets/hr |

| Plate Size (H*W) | Max.1,230*1,130mm, Min. 450*320mm ( can work with KBA Metal Star Series Max. Tinplate Format 1,220 x 1,095 x 0.40mm) |

| Plate Thickness | 0.15-0.40mm |

| Repeat Precision | +/-5 um |

| Mesh Re-Indication (Dot Percentage Area) |

1%~99% |

| Registration Precision | <0.01mm Margin-auto-laser-inspection & auto registration |

| Positioning Precision | 0.2mm |

| Laser Service Life | Min. 10,000 hrs |

| Blowing Chiller | Built-in |

| Remote Diagnosis | Available . |

| Dusting System | Built-in |

| Plates Available | Thermo CTP Plate |

| Diode Laser Feature | Intelligent, Auto-screening, Extended Service Life |

| Plate Load & Unload | Auto Loading, Auto Unloading; Vacuum Sucking |

| Plate Balancing | Auto balancing |

| Data Interface | USB,1,000Mbit/s |

| Constant Temperature. Control | Auto Temperature Equilibrator |

| Working Condition | 25℃+3℃ operation temp. 20~80%relative humidity |

| Machine Dimension | 2,200mm*1,100mm*1,050mm |

| N.W. | 1,500Kg |

| Electricity | 4.2KW/220V+5%,50/60Hz |

| Port | CIP3/CIP4 |

| Light Roller Rotate Speed | 800rpm-900rpm Industry AVG. 600rpm; 50% higher Stability than usual with smaller size drum |

| Plate-in Method | High Pressure Air, Touch-free Plate-in |

| Plate Absorb Method | 3 Chamber Sucking, Auto Sucking Area Adjustable subject to Plate Size, Free of Waving & Floating |

| Optic Lens Running Method | maglev |

| Line-adding Method | Frequency-adjustable, Format-adjustable, Mix-adding methods. Bi-digital halftone processing specially for metal printing. Dot output ratio control for color deviation. |

| Color Management | In-line with types of presses, Output preset data for printing |

| Processor Data. | 1. Connection method: straight ; 2. PLC touch screen panel, problem auto indication ; 3. Precisely control 0.1℃ ; 4. Auto dynamic/static rehydration system ; 5. Auto glue-cleaning, and glue recycling, auto-lubrication; 6. Max processing size 1250mm ; 7. Plate thickness:0.15mm~0.40mm ; |

| Stacker (1 SET) | 1. Auto-stacking ; 2. Suit to CTP system request ; |

| Conveyor (1SET) | 1. Straight conveyor; 2. Suit to CTP system request ; |

| CTP server (1SET) | fits CTP system request, operation system pre-installed. |

| UPS | UPS 10KW Built-in Battery, In-line |

| CTP Control Computer | CPU:Dual-core,Memory:4G,Storage:500G |

STP-S THERMAL CTP PLATE

ALLSTP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

Description:

STP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

SPECIFICATION

Type: Positive Thermal CTP plate;

Spectral Sensitivity: 830nm;

Exposure Energy: 110~130mj/cm²;

Resolution: 200 lpi( 1~99% );

Run-length: 100,000~200,000 ( UV-INK );

200,000~400,000 ( Ordinary ink );

*Run-Length varies with its printing conditions and imaging content

ADVANTAGES

(1) UV-ink resistance;

(2)Low energy required;

(4)Compatible with all standard CTP setters;

| Item | Specifications |

| Structure | External Drum Type |

| Light | 830nm Laser Diode |

| Precision | 2,400dpi |

| Speed | Min. 12sheets/hr |

| Plate Size (H*W) | Max.1,230*1,130mm, Min. 450*320mm ( can work with KBA Metal Star Series Max. Tinplate Format 1,220 x 1,095 x 0.40mm) |

| Plate Thickness | 0.15-0.40mm |

| Repeat Precision | +/-5 um |

| Mesh Re-Indication (Dot Percentage Area) |

1%~99% |

| Registration Precision | <0.01mm Margin-auto-laser-inspection & auto registration |

| Positioning Precision | 0.2mm |

| Laser Service Life | Min. 10,000 hrs |

| Blowing Chiller | Built-in |

| Remote Diagnosis | Available . |

| Dusting System | Built-in |

| Plates Available | Thermo CTP Plate |

| Diode Laser Feature | Intelligent, Auto-screening, Extended Service Life |

| Plate Load & Unload | Auto Loading, Auto Unloading; Vacuum Sucking |

| Plate Balancing | Auto balancing |

| Data Interface | USB,1,000Mbit/s |

| Constant Temperature. Control | Auto Temperature Equilibrator |

| Working Condition | 25℃+3℃ operation temp. 20~80%relative humidity |

| Machine Dimension | 2,200mm*1,100mm*1,050mm |

| N.W. | 1,500Kg |

| Electricity | 4.2KW/220V+5%,50/60Hz |

| Port | CIP3/CIP4 |

| Light Roller Rotate Speed | 800rpm-900rpm Industry AVG. 600rpm; 50% higher Stability than usual with smaller size drum |

| Plate-in Method | High Pressure Air, Touch-free Plate-in |

| Plate Absorb Method | 3 Chamber Sucking, Auto Sucking Area Adjustable subject to Plate Size, Free of Waving & Floating |

| Optic Lens Running Method | maglev |

| Line-adding Method | Frequency-adjustable, Format-adjustable, Mix-adding methods. Bi-digital halftone processing specially for metal printing. Dot output ratio control for color deviation. |

| Color Management | In-line with types of presses, Output preset data for printing |

| Processor Data. | 1. Connection method: straight ; 2. PLC touch screen panel, problem auto indication ; 3. Precisely control 0.1℃ ; 4. Auto dynamic/static rehydration system ; 5. Auto glue-cleaning, and glue recycling, auto-lubrication; 6. Max processing size 1250mm ; 7. Plate thickness:0.15mm~0.40mm ; |

| Stacker (1 SET) | 1. Auto-stacking ; 2. Suit to CTP system request ; |

| Conveyor (1SET) | 1. Straight conveyor; 2. Suit to CTP system request ; |

| CTP server (1SET) | fits CTP system request, operation system pre-installed. |

| UPS | UPS 10KW Built-in Battery, In-line |

| CTP Control Computer | CPU:Dual-core,Memory:4G,Storage:500G |

STP-S THERMAL CTP PLATE

ALLSTP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

Description:

STP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

SPECIFICATION

Type: Positive Thermal CTP plate;

Spectral Sensitivity: 830nm;

Exposure Energy: 110~130mj/cm²;

Resolution: 200 lpi( 1~99% );

Run-length: 100,000~200,000 ( UV-INK );

200,000~400,000 ( Ordinary ink );

*Run-Length varies with its printing conditions and imaging content

ADVANTAGES

(1) UV-ink resistance;

(2)Low energy required;

(4)Compatible with all standard CTP setters;

| Item | Specifications |

| Structure | External Drum Type |

| Light | 830nm Laser Diode |

| Precision | 2,400dpi |

| Speed | Min. 12sheets/hr |

| Plate Size (H*W) | Max.1,230*1,130mm, Min. 450*320mm ( can work with KBA Metal Star Series Max. Tinplate Format 1,220 x 1,095 x 0.40mm) |

| Plate Thickness | 0.15-0.40mm |

| Repeat Precision | +/-5 um |

| Mesh Re-Indication (Dot Percentage Area) |

1%~99% |

| Registration Precision | <0.01mm Margin-auto-laser-inspection & auto registration |

| Positioning Precision | 0.2mm |

| Laser Service Life | Min. 10,000 hrs |

| Blowing Chiller | Built-in |

| Remote Diagnosis | Available . |

| Dusting System | Built-in |

| Plates Available | Thermo CTP Plate |

| Diode Laser Feature | Intelligent, Auto-screening, Extended Service Life |

| Plate Load & Unload | Auto Loading, Auto Unloading; Vacuum Sucking |

| Plate Balancing | Auto balancing |

| Data Interface | USB,1,000Mbit/s |

| Constant Temperature. Control | Auto Temperature Equilibrator |

| Working Condition | 25℃+3℃ operation temp. 20~80%relative humidity |

| Machine Dimension | 2,200mm*1,100mm*1,050mm |

| N.W. | 1,500Kg |

| Electricity | 4.2KW/220V+5%,50/60Hz |

| Port | CIP3/CIP4 |

| Light Roller Rotate Speed | 800rpm-900rpm Industry AVG. 600rpm; 50% higher Stability than usual with smaller size drum |

| Plate-in Method | High Pressure Air, Touch-free Plate-in |

| Plate Absorb Method | 3 Chamber Sucking, Auto Sucking Area Adjustable subject to Plate Size, Free of Waving & Floating |

| Optic Lens Running Method | maglev |

| Line-adding Method | Frequency-adjustable, Format-adjustable, Mix-adding methods. Bi-digital halftone processing specially for metal printing. Dot output ratio control for color deviation. |

| Color Management | In-line with types of presses, Output preset data for printing |

| Processor Data. | 1. Connection method: straight ; 2. PLC touch screen panel, problem auto indication ; 3. Precisely control 0.1℃ ; 4. Auto dynamic/static rehydration system ; 5. Auto glue-cleaning, and glue recycling, auto-lubrication; 6. Max processing size 1250mm ; 7. Plate thickness:0.15mm~0.40mm ; |

| Stacker (1 SET) | 1. Auto-stacking ; 2. Suit to CTP system request ; |

| Conveyor (1SET) | 1. Straight conveyor; 2. Suit to CTP system request ; |

| CTP server (1SET) | fits CTP system request, operation system pre-installed. |

| UPS | UPS 10KW Built-in Battery, In-line |

| CTP Control Computer | CPU:Dual-core,Memory:4G,Storage:500G |

STP-S THERMAL CTP PLATE

ALLSTP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

Description:

STP-S combines so many excellent capacities, high sensitivity, high Run-Length, and Anti UV-INK, it is the ideal choice for Medium and high-end printing user.

SPECIFICATION

Type: Positive Thermal CTP plate;

Spectral Sensitivity: 830nm;

Exposure Energy: 110~130mj/cm²;

Resolution: 200 lpi( 1~99% );

Run-length: 100,000~200,000 ( UV-INK );

200,000~400,000 ( Ordinary ink );

*Run-Length varies with its printing conditions and imaging content

ADVANTAGES

(1) UV-ink resistance;

(2)Low energy required;

(4)Compatible with all standard CTP setters;

Related Products